The PT fuel system is a symbol that distinguishes Cummins diesel engines from other diesel engines. Its distinguishing letter PT stands for pressure and time, while P refers to the fuel pressure at the inlet of the injector. T refers to the effective time for allowing fuel to flow into the fuel injector cup.

https://www.kysoncn.com/diesel-engine-assembly/k19-kta19-excavator-diesel-engine-parts-pt.html

1, The characteristics of PT fuel system are (1) injection pressure range of up to 10000-20000PSI (PSI is pounds per square inch, approximately 6.89476kPa), which can ensure good fuel atomization. The maximum fuel pressure output by PT fuel pump shall not exceed 300 PSI. (2) All fuel injectors share a fuel supply pipe, so even if some air enters the fuel system, it will not cause the engine to stall. (3) PT oil pump does not require timing adjustment, the oil volume is controlled by the oil pump and nozzle, and the engine power can be maintained stably without power loss. (4) About 80% of the fuel is used to cool the injectors before returning to the fuel tank, and the injectors are well cooled. (5) Good universality, with some adjustments made to the same basic pump and injector, it can be applied to the power and speed changes of different engine models over a wide range.

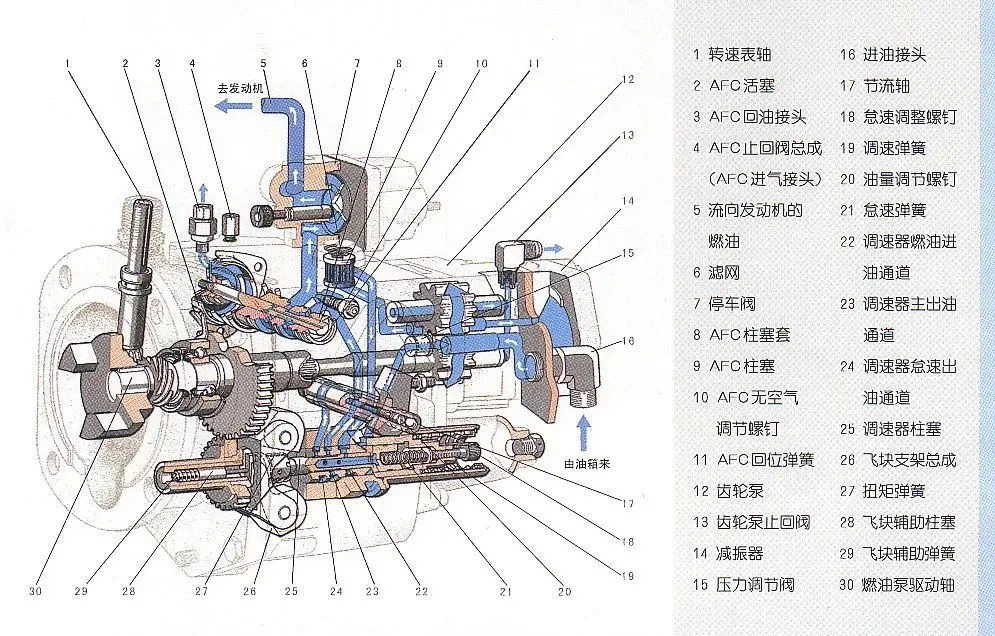

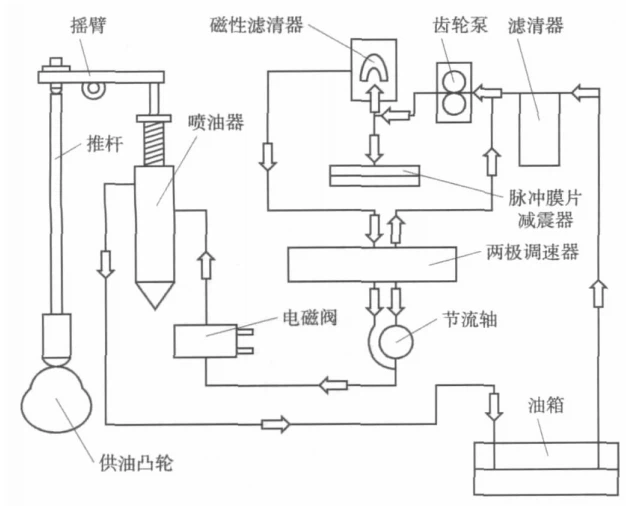

The basic components of PT fuel system consist of fuel tank, fuel filter, PT fuel pump, low-pressure fuel delivery pipe, injector, rocker arm, push rod, injection cam and return pipe. Among them, PT fuel pump includes gear pump, magnetic filter, pulse diaphragm damper, two pole governor, throttle shaft, and solenoid valve. The fuel system diagram of the engine is shown in Figure 1, and the fuel flow diagram is shown in Figure 2.

Figure 1 Engine Fuel System Diagram

Figure 2 Schematic diagram of engine fuel flow

The fuel pump draws fuel from the fuel tank, passes it through the filter and governor, and sends it to the fuel injectors. According to the design of the PT system, about 80% of the fuel supplied by the PT pump to the fuel injectors will return to the fuel tank through the injectors during operation, mainly for cooling and lubricating the fuel injectors. It also has the function of preventing fuel freezing during cold weather and bringing back air from the PT system to the fuel tank for discharge.

2, Common troubleshooting of PT fuel system. (1) When the engine has difficulty starting or cannot be started, the power is insufficient, or it cannot be stopped or turned off, it is generally judged as a malfunction of the parking valve. Firstly, use the manual shaft to open and close the parking valve. Screw the manual shaft in until it can no longer be turned, which is called opening. When parking, unscrew the manual shaft until it can no longer be turned. Next, disassemble the parking valve, clean the parts of the parking valve, and grind the inner hole of the valve body with sandpaper. (2) When the engine is running at an unstable speed, first remove the EFC electronic actuator. Loosen the mounting screws, then rotate the EFC actuator 15 °, remove and clean the actuator, and then reinstall the fuel pump body according to the following method: insert the actuator into the fuel pump body until the actuator flange is about 9.5mm away from the fuel pump body, then gently push the actuator into the fuel pump EFC mounting hole with your palm and rotate it 30 ° until the actuator flange touches the fuel pump body. Tighten the installation screw clockwise from the bottom, first tighten by hand until it can no longer be turned, and then tighten with a wrench. Additionally, check if the shock absorber diaphragm is depressed or if there are any hidden cracks. First remove the shock absorber, then disassemble the shock absorber and check if the shock absorber diaphragm is recessed or if it falls onto a hard surface with a crisp sound. If the sound is muffled, the shock absorber diaphragm needs to be replaced. (3) When the engine with AFC accelerates and there is excessive smoke or insufficient power, the airless adjustment screw can be adjusted (only applicable to single spring AFC when the airless adjustment screw is on the fuel pump body); If the smoke is high, screw it into the pump body; Insufficient power, twist outward. Attention: Twisting in and out is limited to within half a turn. (4) If the engine power is insufficient for the full range pump and generator pump, the throttle shaft throttle can be appropriately increased, that is, the front limit screw can be retracted. If the fuel pump or throttle shaft is not locked at full throttle, the throttle cannot be changed. (5) When adjusting the idle speed of the fuel pump, the idle speed of the fuel pump can be adjusted because the idle speed adjusted on the test bench is the same value, but the adapted host varies greatly. The idle speed of the two pole speed controller is adjusted inside the two pole spring group housing, and the idle speed adjustment screw of the VS speed controller is used for idle speed adjustment. (6) Replace the filter element in the front filter of the parking valve. Note that when installing the filter element, the small hole should face inward and the large end of the spring should be outward. (7) Replace the O-ring and spring of the fuel injector. When replacing, ensure that no dirt enters the fuel injector cavity. After replacing the spring, reinstall the fuel injector plunger, ensuring that it is clean and free of dirt, and that it rotates smoothly without obstruction. In addition, the PT fuel system has high requirements for fuel cleanliness, and most faults are mainly caused by poor fuel cleanliness and excessive impurities, resulting in damage to the fuel pump. Therefore, selecting high-quality and high cleanliness fuel, using genuine filter cartridges, and proper maintenance are the prerequisites for the normal operation of the PT system.